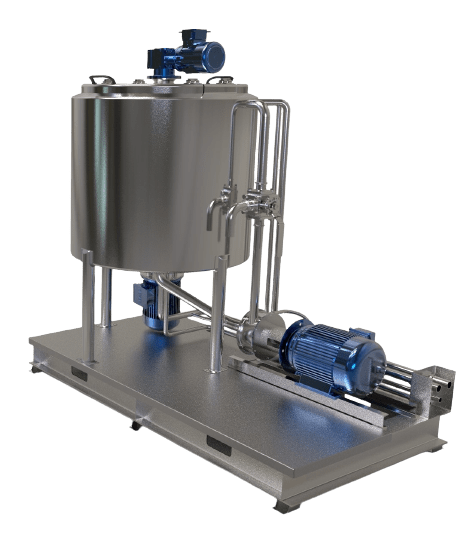

- Sugar Syrup Preparation Unit

- Beverage Blending Section

- Sterilization Section

- Filling section

- Clean–In–Place System

Overview

Beverage Processing Plant

TechQu proposes high-level solutions for pasteurization and sterilization of a wide range of products such as Beverage Products. Our expertise in cost effective design, bespoke manufacturing, automation, installation and after sales services has allowed us to be the turnkey solution. Beverage processing starts from preparation section and continues till pasteurization. This integrated beverage processing line includes sugar syrup preparation, pulp unloading, ingredient dosing sections, beverage blending section, ready beverage storage section, beverage pasteurizer and a centralized CIP station.

A beverage processing plant is a facility where ingredients are mixed, blended, and processed to create various types of beverages such as soft drinks, juices, energy drinks, and other liquid products. The process typically includes several steps such as:

- Ingredient preparation: ingredients are prepared and measured according to the recipe.

- Mixing and blending: ingredients are mixed and blended together in a blending tank to create the final product.

- Pasteurization: The juice is heated to kill any bacteria and extend its shelf life.

- Filtration: The juice is filtered to remove any remaining impurities.

- Carbonation: Carbon dioxide is added to create carbonated drinks.

- Packaging: The beverage is packaged in bottles, cans, or pouches.

- Storage: The beverage is stored in a cool, dry place until it is ready to be shipped to customers.

Explore

Related Products