What Is Beverage Processing Business?

The beverage processing business involves the manufacturing and processing of various types of beverages for consumption. This can include alcoholic beverages such as beer, wine, and spirits, as well as non-alcoholic beverages like soft drinks, fruit juices, energy drinks, bottled water, tea, and coffee.

Is Beverage Processing Business Profitable?

The profitability of a beverage processing business can vary depending on various factors such as market demand, competition, production costs, branding, distribution channels, and efficiency of operations. However, generally speaking, beverage processing can be a profitable business if managed effectively.

Eight Steps To Follow Profitable Beverage Processing Business.

Starting a profitable beverage processing business requires careful planning, market research, and execution. Here are eight steps to follow:

- Business Plan:

Develop a detailed business plan outlining your goals, target market, products, production process, marketing strategy, and financial projections.

- Choose a Location Of Beverage Processing Factory:

Choosing the right location for your beverage processing factory is a critical decision that can impact your profitability and long-term success. Here are some key factors to consider:

- Raw Materials

- Market Access & Distribution

- Workforce and Regulations

- Additional Considerations

- Name Your Beverage Processing Business:

Here are some ideas for naming your beverage processing business, considering different approaches:

- Descriptive Names

- Creative & Catchy Names

4. Make The Business Legally Compliant:

Making your beverage processing business legally compliant involves several steps. Here’s a breakdown of the key areas to focus on:

- Business Registration

- Licenses and Permits

- Food Safety and Labeling

- Additional Considerations

5. Machine & Equipment for Beverage Processing:

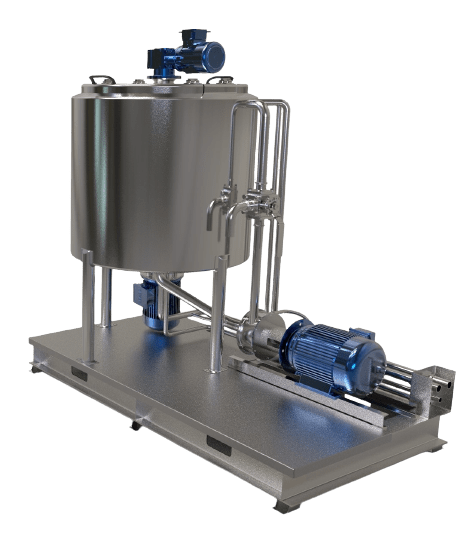

- · Mixing and Blending Equipment

- · Processing Tanks

- · Filtration Systems

- · Heat Exchangers

- · Pasteurization Equipment

- · Bottling and Canning Machines

- · Carbonation Systems

- · Distillation Equipment

- · Quality Control Equipment

- · Cleaning and Sanitization Equipment

6. Cost of Starting Beverage Processing Unit:

The cost of starting a beverage processing unit can vary significantly depending on various factors such as the scale of production, type of beverages produced, location, regulatory requirements, and equipment choices.

7. Beverage Manufacturing Process:

The beverage manufacturing process can be broken down into several key stages, though the specifics will vary depending on the type of beverage being produced. (e.g., soft drinks, beer, wine, spirits, fruit juices, bottled water, tea, coffee, etc.).

8. Promate Your Products:

Here are some strategies you can use to promote your beverage product and build a successful brand:

- Develop a Strong Brand Identity

- Leverage Social Media Marketing

- Public Relations and Media Outreach

- Utilize Content Marketing

- Implement Targeted Advertising

- Offer Promotions and Samplings

- Participate in Industry Competitions

- Focus on Customer Experience

Explore

Related Products